Insights

better business decisions

Posted 3 years ago | 5 minute read

The concrete challenge

Concrete is one of most used materials on the planet and society relies on many forms of concrete, from the pavers that we walk on to the high-performance structural concrete used in construction. But the manufacture of the material is energy-intensive and high carbon.

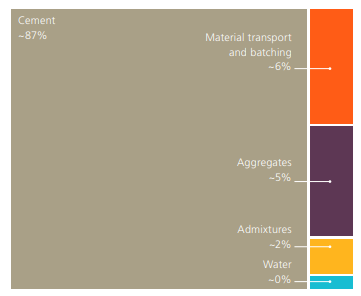

UK concrete and cement currently account for around 1.5% of UK carbon emissions, five times lower than the global average. In addition, early action by the industry has resulted in emissions already being 53% lower than 1990. But the scale of the net zero challenge requires the wholesale decarbonisation of all aspects of concrete and cement production, supply and use. It is estimated that up to 90% of the greenhouse gas (GHG) emissions associated with the production of concrete are down to the Conventional Portland cement as the process of heating and decomposing the limestone releases about 0.86kg CO2 e for every 1kg of cement produced.

Distribution of embodied carbon in a typical structural concrete

Source: Low Carbon Concrete Routemap

In a recent report published the Low Carbon Concrete Group (LCCG), The Green Construction Board and the Institute for Civil Engineering set out a roadmap for decarbonising the sector. Published on 27 April, the Low Carbon Concrete Routemap examines how the infrastructure industry can use the latest tools, technologies and materials to continue using concrete while working towards a zero-carbon future.

It makes wide-ranging recommendations for clients and industry in seven strands

- Setting the benchmark – the report noted that a zero-carbon future for concrete can only be mapped out from an accurate starting position. The LCCG has been working with industry to establish appropriate boundaries to classify concrete by embodied carbon. Further work is required to build on this data and establish a simple rating system for carbon in concrete. The report called for cross-industry efforts to standardise measuring, reporting and benchmarking of the greenhouse gases associated with different types of concrete

- Knowledge transfer – Knowledge transfer is crucial to addressing barriers and accelerating the use of lower-carbon concrete. There needs to be clear guidance on how to specify, design and use lower-carbon concretes within the existing and emerging standards, challenging them if necessary, as well as a better understanding of performance and how and when to engage with stakeholders. There needs to be an agreed approach to the embodied carbon values used for concrete constituents. It also said coordination between institutions and trade bodies is important to ensure guidance is effective and that a coordinated approach between the client, industry and government will help optimise the benefits of concrete for carbon. Embedding the requirement to address CO2 e within the whole supply chain.

- Design and specification – The use of concrete must be optimised within the design process regardless of its carbon intensity. Guidance that demonstrates how material savings can be made through efficient design is required. The specification of concrete

and concrete products must include appropriate carbon intensity, and specifiers need to understand how they can work to reduce it while meeting other performance requirements.

- Supply and construction – Consideration must be given to how a concrete will be produced and whether in-situ or precast concrete offers

greater potential carbon savings. The performance requirements, installation method and project-specific logistical constraints should all be considered during early collaboration between the concrete producer and the project team. There must also be a clear plan for verification of the material to avoid waste or an excessive testing regime.

- Optimising existing technology – Within current standards and practice, it is possible to produce concretes that have lower embodied carbon. To achieve this, stakeholders need to work together to ensure that all options for cement types are considered. In addition, the project team must work to ensure that the cement content is optimised for a given cement type. Collectively this optimised approach will realise significant carbon savings over typical practice. It must also consider the limited availability of the most common currently available SCMs and seek to use them as efficiently as possible to reduce carbon emissions

- Adopting new technology – Concretes that use other cements or constituents outside of current standards will be part of the overall solution to reducing the carbon intensity of the industry. Some of these concretes are an extension of existing technology, while others adopt wholly different chemistry. Wherever possible and appropriate, these new technologies should be supported by the industry to allow the accelerated development of standards and an increase in commercial readiness and application.

- Carbon sequestration, capture and use – Carbon sequestration within concrete can offer some benefit in performance. Guidance on how to use novel carbon curing technology and a better understanding of how to maximise long-term carbonation are required. Carbon capture technology to reduce the intensity of cement production requires large-scale industry and government support and should be recognised as an end-of-pipe solution that should be developed with, not instead of, other carbon-saving approaches. Sequestering captured CO2 into new SCMs and aggregates should be supported and accelerated.

Working collaboratively with stakeholders across the sector, a new UK Concrete Decarbonisation Taskforce, convened by the ICE, will oversee the delivery of the Routemap to unlock major step changes in the decarbonisation of concrete.

GridBeyond works with aggregates, asphalt, cement, concrete, dimension stone, lime, mortar, and silica sand to boost sustainability credentials and create new revenue and savings opportunities. Learn more